Oscar Emiliano Rodriguez Flores

Engineering Portfolio

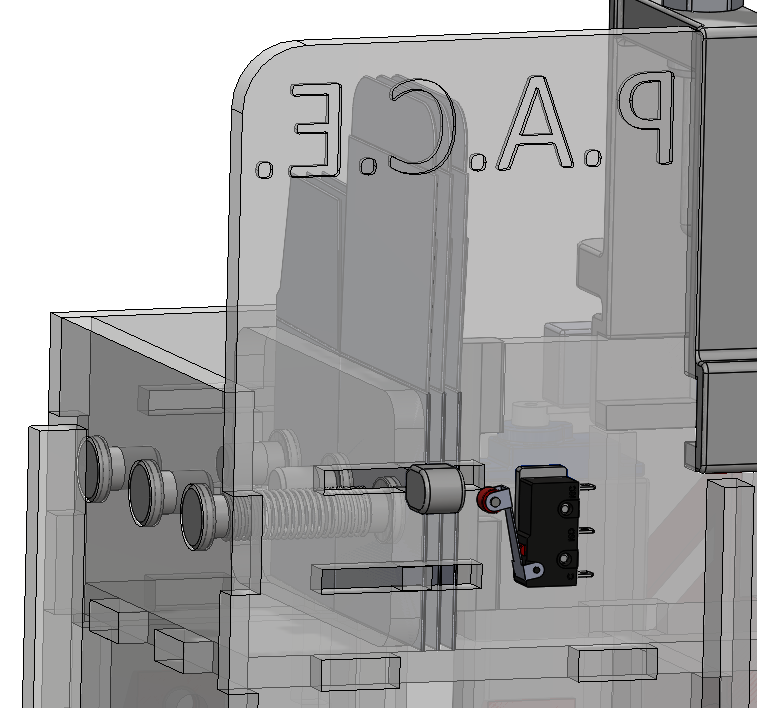

P. A. C. E.

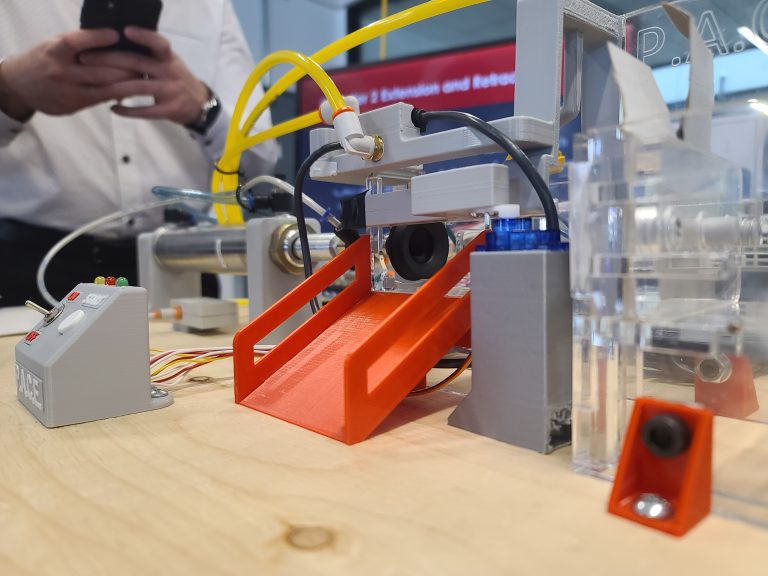

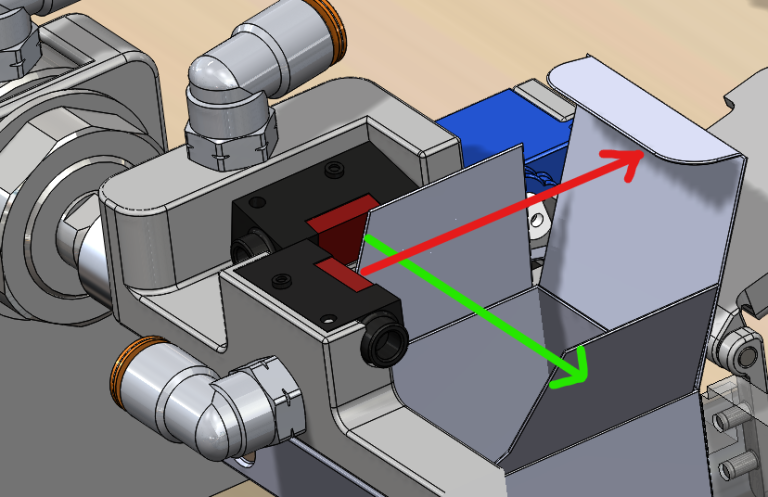

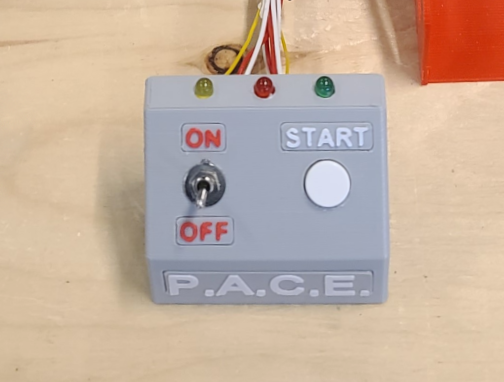

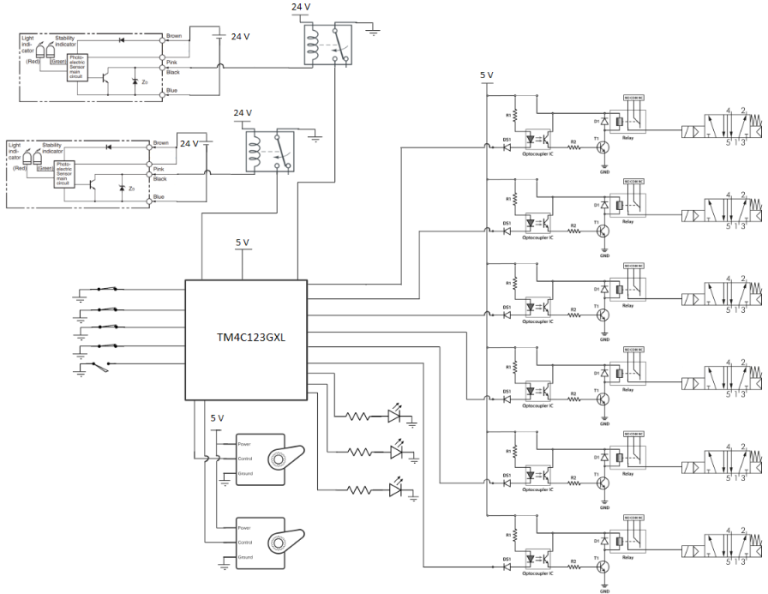

This system leverages the power of pneumatic components, seamlessly integrated with an array of sensors and electronic components. These intelligent sensors continuously monitor the system’s status, efficiently detecting any issues that may arise during the box-opening journey. The entire operation is controlled by a microcontroller, serving as the brain of the system and ensuring precise control and seamless automation.

Process

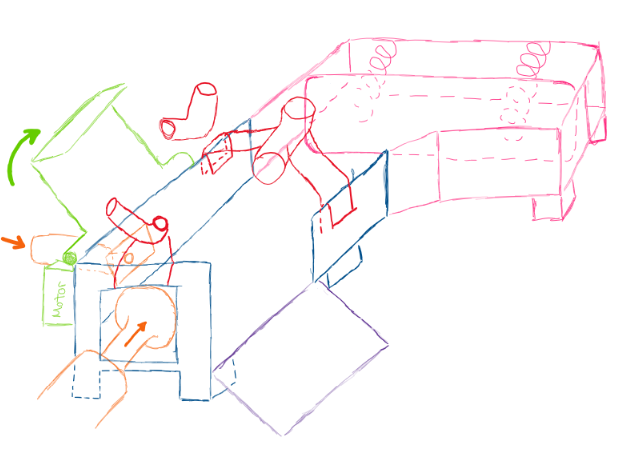

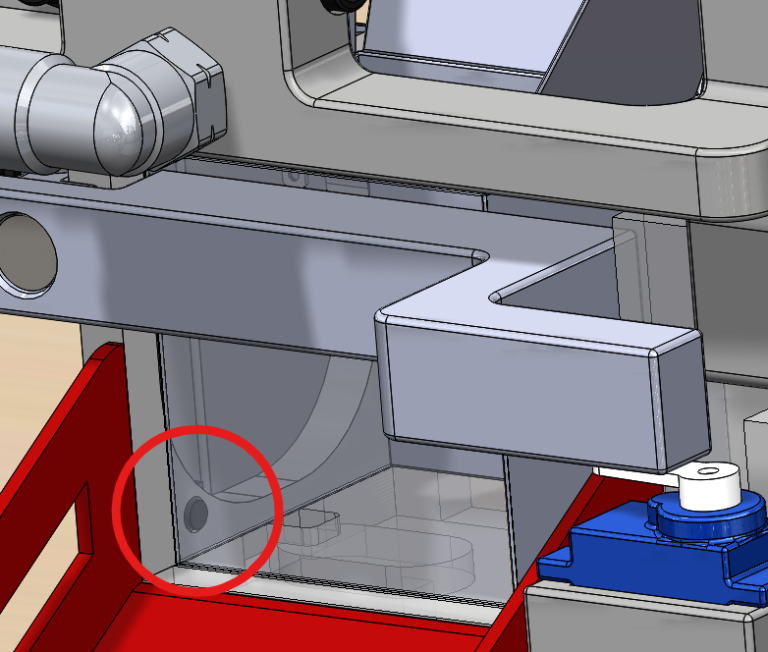

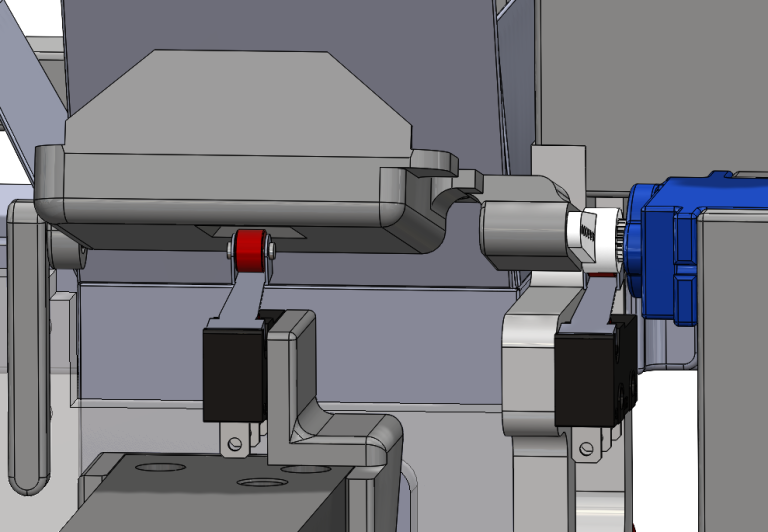

The journey commenced with a collaborative brainstorming session, where ideas were conceptualized and sketched to outline the project’s approach. The pivotal concept centered around the utilization of nozzles, directing pressurized air strategically to the box flaps, facilitating their closure. To bring this vision to life, the team transitioned to SolidWorks, meticulously modeling the system. The design incorporated real CAD models of high-quality components sourced from reputable companies like Omron and Festo for the pneumatic elements. With a detailed plan in hand, the manufacturing phase unfolded. Employing advanced techniques, custom-made parts were crafted using 3D printing, while the machine’s structure took form through precision laser cutting of acrylic materials.

Main Features

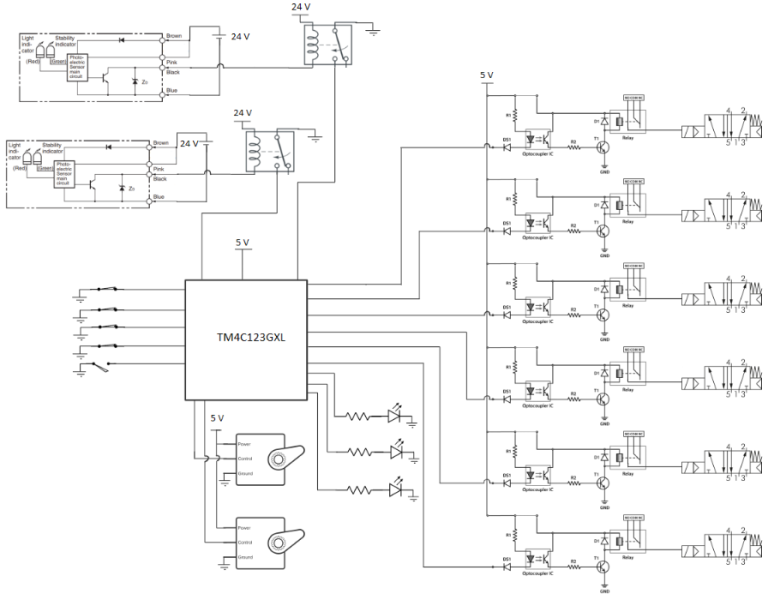

To maintain continuous monitoring and ensure seamless consistency, a network of sensors was strategically integrated throughout the system. This included photoelectric sensors, designed to detect any flaps that remained ajar after an attempted closure, prompting the system to initiate another closing sequence. A strategically placed push button at the end of the pathway served a dual purpose—detecting the box’s arrival at the closing position and monitoring the seal in the suction cup. If the seal was broken, indicating a loss of pressure, the button would cease to apply pressure. Additionally, the precision control of the servo motor’s position was facilitated by the use of limit switches. These switches not only ensured positional accuracy but also helped determine whether the magazine was still loaded with boxes, adding an extra layer of operational insight to the system.

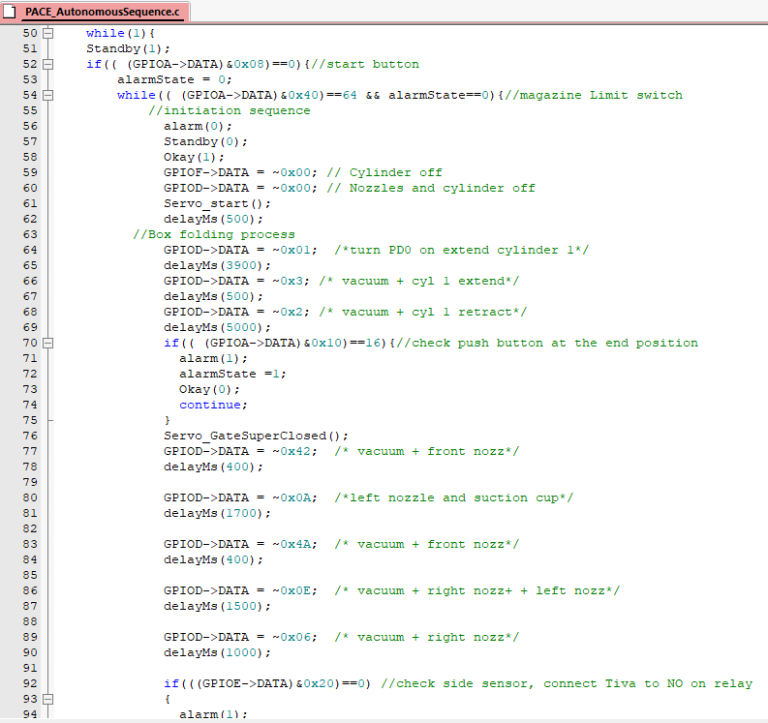

Programming

We employed a TM4 C123G microcontroller from Texas Instruments. What sets our project apart is the meticulous coding crafted entirely in C, where we avoided the use of pre-made libraries, opting to develop every line of code from scratch. This deliberate choice underscores our commitment to a deep understanding of our system.

For a deeper dive into the intricacies of this project, I invite you to explore my GitHub repository!